Do Mechanical Seals Require Lubrication? A Comprehensive Guide

Mechanical seals are critical components in many industrial applications, including pumps, compressors, and mixers. They are designed to prevent leakage of fluids and gases from the equipment, ensuring safe and efficient operation. One question that often arises is whether mechanical seals require lubrication. In this article, we will explore this topic in detail and provide a comprehensive guide to mechanical seals and lubrication.

What are Mechanical Seals?

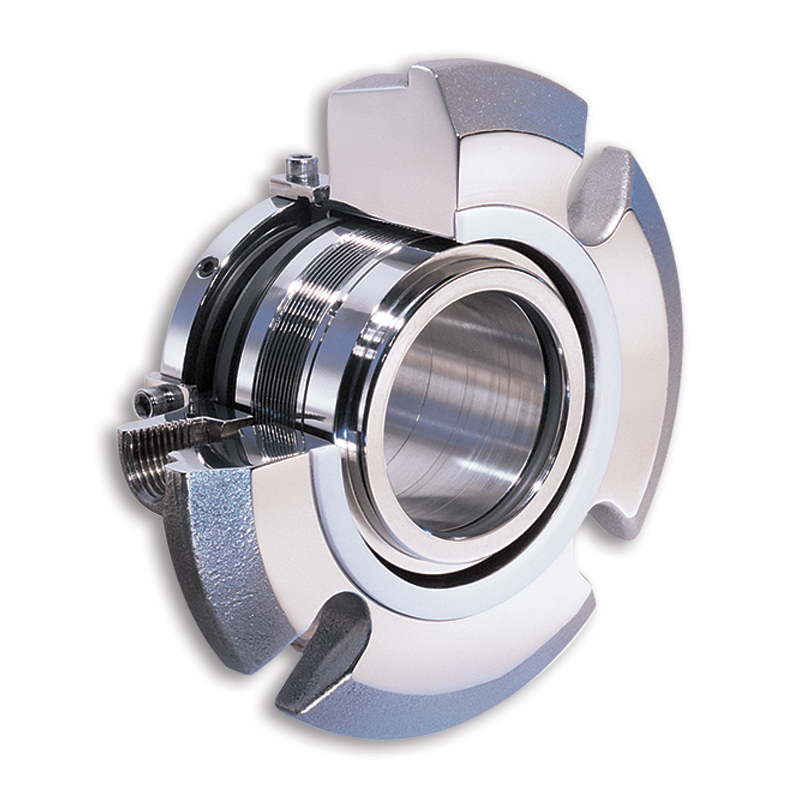

Mechanical seals are devices that create a static seal between two surfaces in relative motion. They consist of two main components: a stationary part and a rotating part. The stationary part is typically mounted on the equipment housing, while the rotating part is attached to the shaft. The two parts are held together by a spring, which creates a seal between them.

Do Mechanical Seals Require Lubrication?

The answer to this question is not straightforward. Some mechanical seals require lubrication, while others do not. The type of mechanical seal and the application it is used in will determine whether lubrication is necessary.

Types of Mechanical Seals:

There are several types of mechanical seals, including:

- Unbalanced Mechanical Seals: These seals are not self-aligning and require external lubrication to prevent wear and tear.

- Balanced Mechanical Seals: These seals are self-aligning and do not require external lubrication.

- Cartridge Mechanical Seals: These seals are pre-assembled and self-contained, requiring no external lubrication.

- Gas-lubricated Mechanical Seals: These seals use a gas, such as nitrogen, to create a barrier between the sealing faces, eliminating the need for external lubrication.

Lubrication Requirements:

For unbalanced mechanical seals, external lubrication is necessary to prevent wear and tear. The lubrication can be provided by the fluid being pumped or by an external source.

For balanced mechanical seals, external lubrication is not required. However, the seal faces must be kept clean and free of debris to prevent damage.

Cartridge mechanical seals are pre-lubricated and self-contained, requiring no external lubrication.

Gas-lubricated mechanical seals use a gas to create a barrier between the sealing faces, eliminating the need for external lubrication.

Conclusion:

In conclusion, the lubrication requirements for mechanical seals depend on the type of seal and the application it is used in. Unbalanced mechanical seals require external lubrication, while balanced mechanical seals, cartridge mechanical seals, and gas-lubricated mechanical seals do not. It is important to understand the lubrication requirements for your specific application to ensure safe and efficient operation.

Average Rating