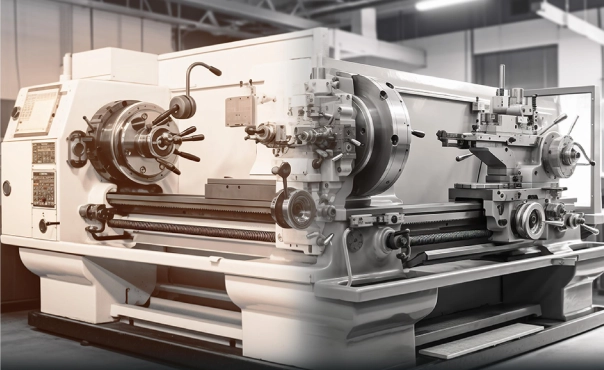

Revealing The Secrets of Building Material Gear: The Key Force and Unique Charm Behind Construction Machinery

With the rapid development of the modern construction industry, the precision and efficiency requirements of mechanical equipment are constantly increasing. As the core component of the transmission device, building material gear plays an indispensable role in construction machinery. In this article, Tianshan will deeply explore the application and technical characteristics of building material gear.

Key Applications of Building Material Gear in Construction Industry

Building material gear is widely used in construction machinery and equipment, such as concrete mixers, tower cranes, excavators, loaders, etc. These equipment play a vital role in construction, and gears, as the core components of the mechanical transmission system, directly affect the working efficiency and service life of the equipment.

Concrete Mixer

The mixing drum of the concrete mixer rotates through the gear transmission system to achieve uniform mixing of concrete. High-quality building material gear can ensure the stable operation of the mixer, reduce failures during mixing, and improve the quality of concrete. During the mixing process, the precision and wear resistance of the gear have a direct impact on the uniformity and work efficiency of the concrete. High-quality gear materials and manufacturing processes can effectively reduce gear wear, extend the service life of the equipment, and reduce maintenance costs.

Tower Crane

The rotating mechanism and lifting mechanism of the tower crane both rely on the gear transmission system. The precision and strength of building material gear are directly related to the working efficiency and safety of the crane. High-quality building material gear can not only withstand huge loads, but also ensure the stable operation of the equipment in a complex working environment. Tower cranes often operate at high altitudes and under heavy loads, so the gears must have extremely high reliability and durability to ensure the safety and efficiency of construction.

Excavators and Loaders

The walking and working devices of construction machinery such as excavators and loaders are all driven by gear systems. The application of building material gear in these equipment requires not only high strength and wear resistance, but also good impact resistance to adapt to various harsh construction environments. In high-intensity operations, gears need to withstand repeated impact and wear, which places extremely high demands on materials and processing technology. By adopting advanced materials and processing technology, the durability and reliability of gears can be significantly improved.

Technical Characteristics of Building Material Gear

As an important part of construction machinery, building material gear has the following technical characteristics:

High Strength and High Hardness

In order to cope with high-load and high-intensity working environments, building material gear usually uses high-strength alloy steel materials and undergoes heat treatment processes such as carburizing and quenching to improve its hardness and wear resistance. High-strength materials can withstand heavy loads, and carburizing and quenching treatment can enhance the hardness and wear resistance of the gear surface, thereby extending the service life of the gear. These process technologies ensure that the gear can operate stably and for a long time under high stress conditions, reducing the failure rate and maintenance cost of the equipment.

High-precision Machining

The accuracy of the gear directly affects the running smoothness and noise level of the transmission system. Modern manufacturing technologies such as CNC machining and gear grinding are widely used in the production process of building material gear to ensure the high precision and high quality of the gear. High-precision gears can ensure the smooth operation of the transmission system, reduce vibration and noise, and improve the overall performance of the equipment. CNC machining and precision gear grinding can achieve micron-level machining accuracy, ensure that each gear can be perfectly matched, and improve the reliability and service life of the equipment.

Good Lubrication and Maintenance Performance

In order to extend the service life of the gear and reduce wear and energy loss, building material gear should pay special attention to the design of the lubrication system during design and manufacturing, and use advanced lubrication materials and technologies. Effective lubrication can not only reduce the friction and wear of the gear, but also reduce the energy loss during operation and improve the transmission efficiency. By adopting an automatic lubrication system and high-performance lubricating oil, it can ensure that the gears always maintain good lubrication state under long-term and high-load conditions, reducing maintenance frequency and cost.

Corrosion Resistance and Weather Resistance

Construction machinery usually works in open-air and complex environments, and gears need to have good corrosion resistance and weather resistance. This is usually achieved by selecting corrosion-resistant materials and surface treatment technologies, such as galvanizing and chrome plating. Anti-corrosion treatment can effectively prevent rust and damage of gears in humid and corrosive environments, and extend the service life of gears. Weathering treatment ensures that gears can still work normally under extreme temperature and climatic conditions and are not affected by environmental changes.

As an important part of construction machinery, the technical level and application quality of building material gear are directly related to the performance and construction efficiency of mechanical equipment. With the continuous advancement of technology and the growth of market demand, building material gear will play a more important role in the construction industry. Enterprises need to continue to innovate and improve their technical level to adapt to market changes and meet customer needs, so as to occupy a place in the fierce market competition. Through continuous technological research and development and quality improvement, building material gear manufacturers will be able to achieve greater success in future development and promote the progress and development of the construction machinery industry.

https://www.tianshangear.com/Metallurgical-Building-Materials-and-Mining-Gear.html

www.tianshangear.com

Changzhou Tianshan Heavy Industry Machinery Co., Ltd

Average Rating