Top Benefits of Using AMADA 1V Dies 30° for Sheet Metal Fabrication

In the world of sheet metal fabrication, precision, efficiency, and tool durability play critical roles in achieving top-quality results. One essential tool that enhances bending accuracy and productivity is the AMADA 1V Dies 30°. These specialized press brake dies are designed to deliver superior performance in metal bending operations. In this article, we’ll explore the key benefits of using AMADA 1V Dies 30° and introduce AE Tooling, a professional tooling manufacturer dedicated to producing high-end press brake tools for fabrication companies worldwide.

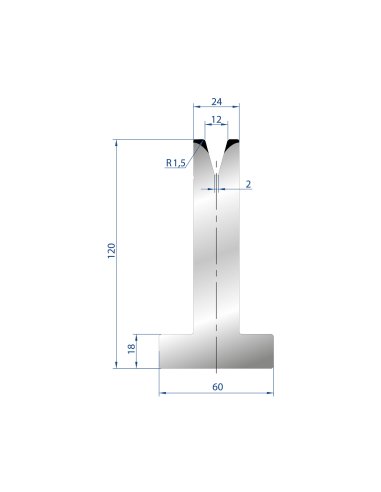

What Are AMADA 1V Dies 30°?

AMADA 1V Dies 30° are precision-engineered press brake tools used in the metal bending process. These dies feature a 30° V-opening angle, making them ideal for achieving precise bends, particularly in applications requiring sharp angles, such as acute bends or small-radius bends in thin and medium-thickness sheet metals.

Top Benefits of Using AMADA 1V Dies 30°

1. Enhanced Bending Accuracy

Precision is key in sheet metal fabrication, and AMADA 1V Dies 30° excel in delivering accurate, consistent bends. The 30° V-opening angle provides tight control over the bending radius, resulting in clean, sharp bends that meet exact specifications. This precision is especially valuable for industries such as aerospace, automotive, and electronics, where accuracy is critical.

2. Versatility for Various Bending Applications

AMADA 1V Dies 30° are versatile tools that can handle a wide range of materials, including aluminum, stainless steel, and mild steel. Their acute angle makes them suitable for producing different bend profiles, from simple 90° bends to complex small-radius bends. This flexibility allows manufacturers to adapt to various project requirements without needing multiple sets of dies.

3. Improved Efficiency and Productivity

By delivering consistent, high-quality bends, AMADA 1V Dies 30° reduce the need for rework and minimize material waste. This boosts overall efficiency and productivity in the workshop. Additionally, their robust design ensures they can withstand high-pressure bending operations, enabling faster processing times and longer tool life.

4. Durability and Long-Term Performance

Made from premium-grade materials, AMADA 1V Dies 30° are built for durability and long-term performance. Their wear-resistant properties help them maintain their shape and precision even after extended use, reducing downtime and maintenance costs for manufacturers.

5. Seamless Integration with Press Brakes

AMADA 1V Dies 30° are designed to integrate seamlessly with AMADA press brakes and other compatible bending machines. This compatibility simplifies setup and ensures optimal performance, making the bending process smoother and more efficient.

AE Tooling: Your Partner for High-End Press Brake Tooling

When it comes to manufacturing top-quality press brake tools, AE Tooling stands out as a trusted industry leader. With extensive expertise in tooling design and production, AE Tooling specializes in developing high-end press brake tools, including custom and standard dies for leading press brake manufacturers and fabrication companies.

Key features of AE Tooling’s products include:

-

Precision Engineering: Every tool is designed and manufactured with meticulous attention to detail, ensuring superior accuracy and performance.

-

High-Quality Materials: AE Tooling uses premium materials to enhance the durability and longevity of its products.

-

Custom Solutions: The company offers tailored tooling solutions to meet specific bending needs, helping clients optimize their metal fabrication processes.

-

Global Reach: With a reputation for excellence, AE Tooling serves clients worldwide, supporting various industries, from automotive and construction to heavy machinery and electronics.

Conclusion

Using AMADA 1V Dies 30° in your sheet metal fabrication process can significantly enhance bending precision, efficiency, and tool longevity. When paired with high-quality press brake tools from AE Tooling, manufacturers can achieve even better results, reducing downtime, improving productivity, and ensuring consistent, high-quality bends.

Whether you’re a fabrication professional or a manufacturer seeking top-tier press brake tooling, AE Tooling and AMADA 1V Dies 30° offer the ideal combination of precision, durability, and versatility to elevate your bending operations.

www.aetooling.com

AE Tooling

Average Rating