How to Effectively Utilize Circulating Fluidized-Bed Technology in Industrial Applications

Circulating Fluidized-Bed (CFB) technology has gained significant traction across various industrial sectors due to its high efficiency, fuel flexibility, and environmental benefits. From power generation to chemical processing, CFB systems provide an innovative solution for improving combustion efficiency and reducing emissions.

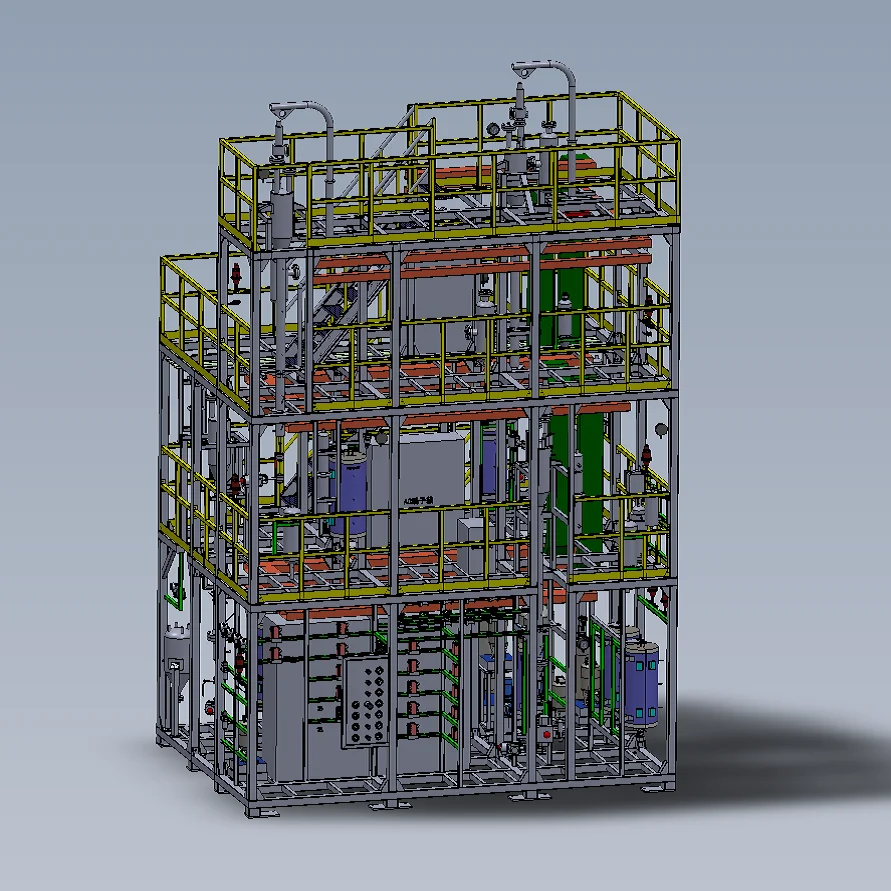

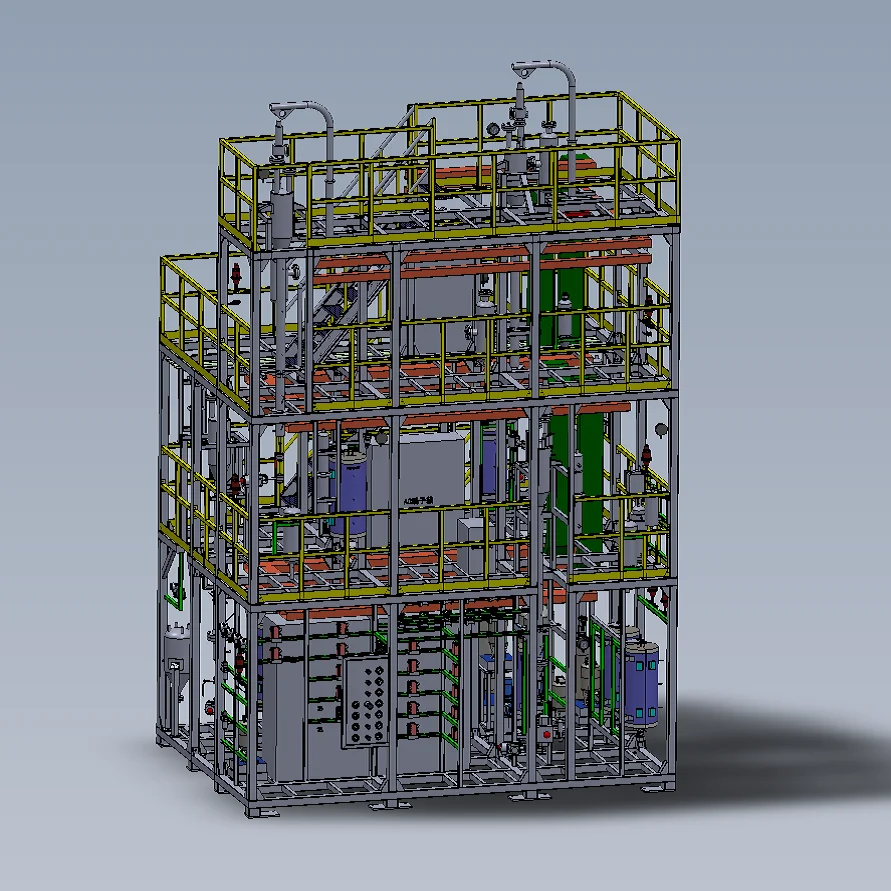

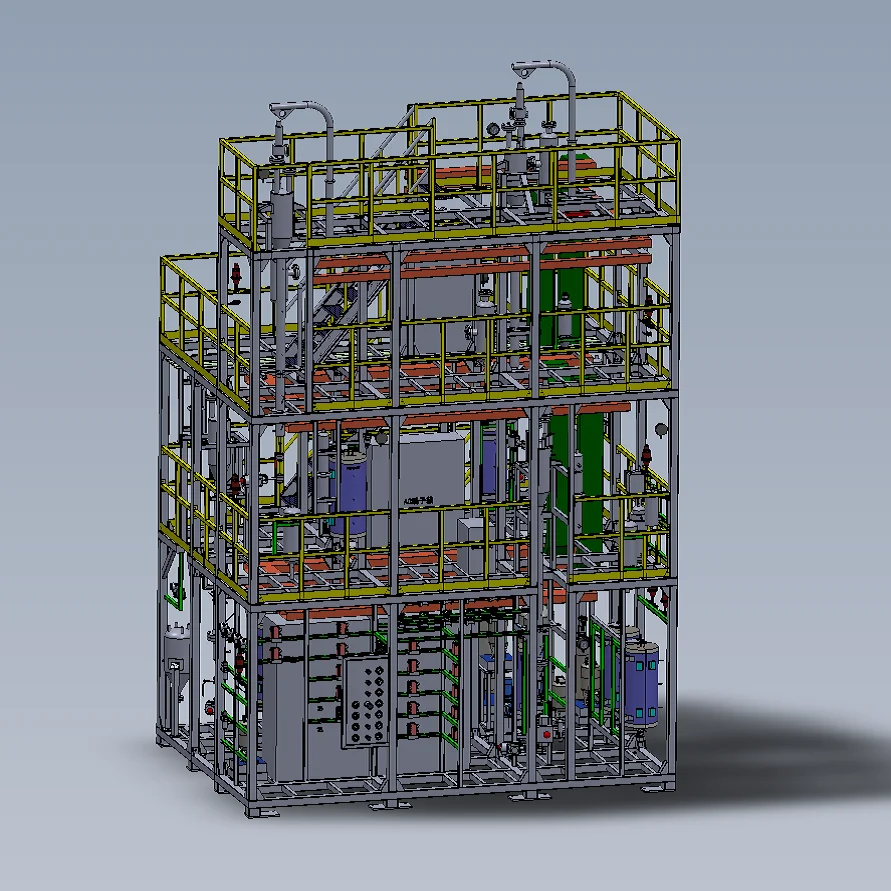

Chem-Unit Technologies Co. Ltd., a leading enterprise specializing in the research, design, manufacturing, and technical services of skid-mounted experimental units, pilot plants, production systems, and human-replacing experimental robots, is at the forefront of advancing CFB technology. This guide explores the key principles, benefits, and industrial applications of CFB technology to maximize its effectiveness.

Understanding Circulating Fluidized-Bed Technology

CFB technology involves the fluidization of solid particles within a high-velocity gas stream, creating a stable, circulating flow that enhances mixing, heat transfer, and reaction efficiency. The process is widely utilized in combustion, gasification, and chemical reactions, offering superior performance compared to conventional methods.

Key Features of CFB Technology:

Fuel Flexibility: Can handle a variety of fuels, including biomass, coal, and waste-derived materials.

High Efficiency: Enhanced mixing leads to improved heat transfer and combustion.

Low Emissions: Reduces NOx and SOx emissions through in-situ desulfurization and lower combustion temperatures.

Scalability: Suitable for small-scale experimental setups to large industrial plants.

Industrial Applications of CFB Technology

1. Power Generation

CFB boilers are widely used in thermal power plants due to their ability to efficiently burn low-grade fuels.

Integrated desulfurization minimizes the need for additional pollution control equipment.

2. Chemical Processing

Used in fluid catalytic cracking (FCC) for refining petroleum products.

Plays a key role in polymerization, where precise temperature control is required.

3. Gasification for Syngas Production

CFB reactors facilitate gasification of biomass and coal into synthesis gas (syngas) for chemical manufacturing and energy applications.

4. Waste-to-Energy Conversion

Efficiently processes municipal solid waste (MSW) and industrial waste into usable energy sources.

5. Metallurgical Industry

Utilized in ore roasting and metal extraction processes to improve reaction efficiency and reduce energy consumption.

Best Practices for Implementing CFB Technology

1. System Design Optimization

Tailor reactor and boiler designs to specific application needs.

Utilize advanced computational fluid dynamics (CFD) simulations for performance enhancement.

2. Material Selection and Maintenance

Choose wear-resistant materials for components exposed to high-velocity particles.

Implement regular maintenance to prevent erosion and ensure longevity.

3. Process Control and Automation

Use real-time monitoring systems to adjust operating parameters dynamically.

Integrate AI-driven predictive maintenance to minimize downtime and operational costs.

4. Environmental Compliance

Employ advanced emission control techniques to meet regulatory standards.

Optimize fuel feed and air distribution to reduce pollutant formation.

Chem-Unit: Advancing CFB Solutions

As a pioneer in industrial technology, Chem-Unit Technologies Co. Ltd. specializes in developing innovative CFB-based solutions tailored for experimental and production-scale applications. Their expertise in designing skid-mounted pilot plants and automated experimental robots ensures high-precision process control, making CFB technology more accessible and efficient for various industries.

Why Choose Chem-Unit Technologies?

Cutting-Edge R&D: Continuous innovation in CFB reactor and combustion systems.

Customizable Solutions: Tailored designs for specific industrial applications.

Comprehensive Technical Support: From pilot testing to full-scale implementation.

Sustainable Focus: Emphasizing energy efficiency and emission reduction.

Conclusion

Effectively utilizing Circulating Fluidized-Bed technology in industrial applications requires a strategic approach that encompasses design optimization, material selection, automation, and environmental compliance. With its versatility and efficiency, CFB technology is a game-changer in industries ranging from power generation to waste-to-energy conversion.

By leveraging the expertise of Chem-Unit Technologies Co. Ltd., businesses can access state-of-the-art CFB solutions that drive innovation, sustainability, and operational excellence.

Understanding Circulating Fluidized-Bed Technology: Methods and Industrial Applications

en.chem-unit.com

Shanghai Chem-Unit Technologies Co. Ltd

Average Rating