What is 3D-Printed Plastic Called: Understanding the Different Types and Applications

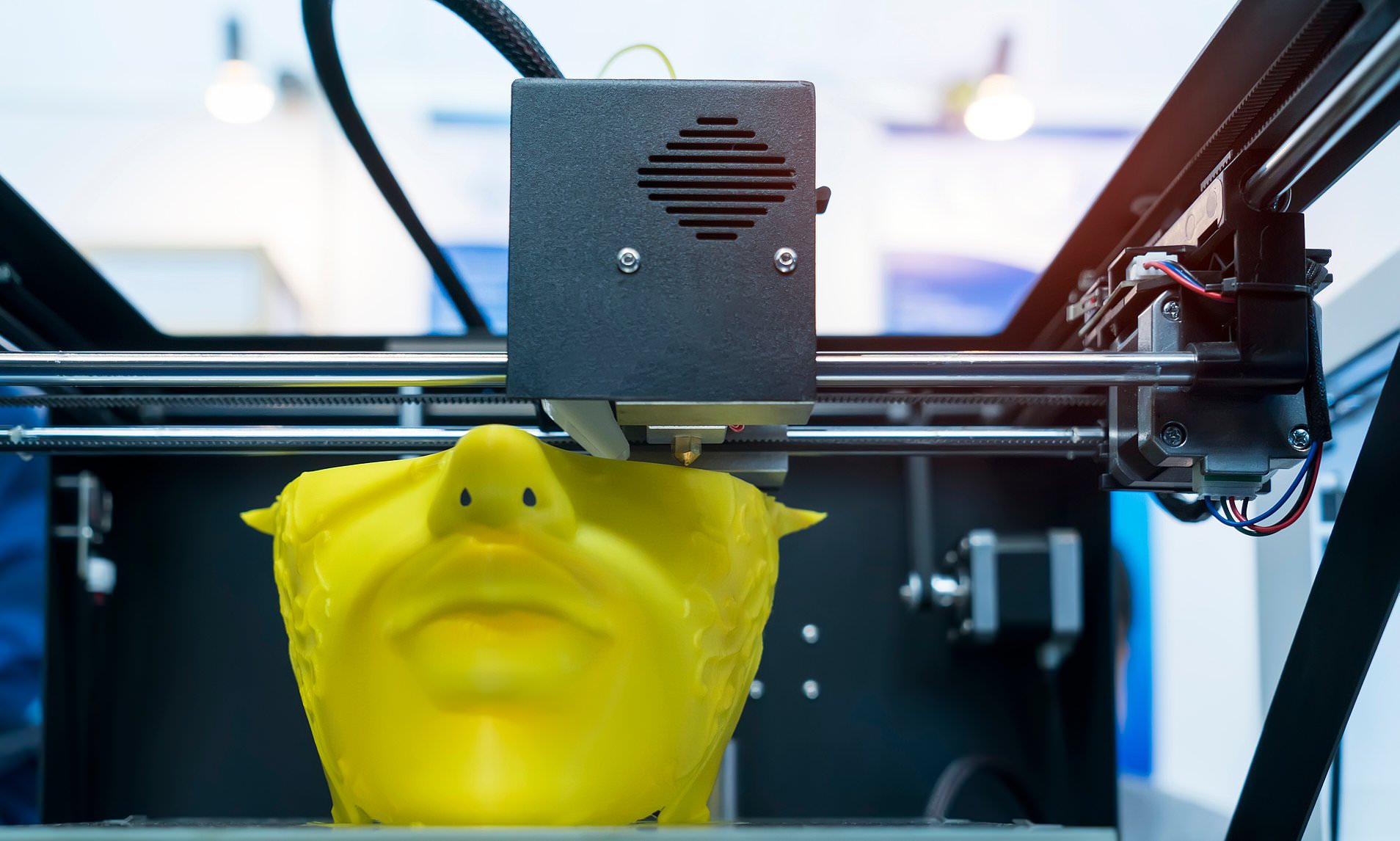

3D printing has revolutionized the manufacturing industry, allowing for the creation of complex and intricate designs with ease. One of the most commonly used materials in 3D printing is plastic, which is affordable, versatile, and easy to work with. But what exactly is 3D-printed plastic called, and what are the different types and applications of this material?

The term used to describe 3D-printed plastic is filament. Filament is a long, thin strand of plastic that is fed into a 3D printer and melted down to create a three-dimensional object. There are several types of filament available, each with its own unique properties and applications.

The most common type of filament is called PLA (polylactic acid). PLA is a biodegradable plastic made from renewable resources such as cornstarch or sugarcane. It is easy to print with, produces high-quality prints, and is environmentally friendly. PLA is often used for prototyping, educational purposes, and creating decorative objects.

Another popular filament is ABS (acrylonitrile butadiene styrene). ABS is a strong and durable plastic that is commonly used in the automotive and electronics industries. It is more difficult to print with than PLA and requires a heated bed to prevent warping. ABS is often used for creating functional parts and objects that require strength and durability.

PETG (glycol-modified PET) is a newer type of filament that combines the best properties of PLA and ABS. It is strong, durable, and easy to print with, but also has a higher temperature resistance than PLA. PETG is often used for creating functional parts, such as mechanical components and enclosures.

Nylon is another popular filament that is known for its strength and flexibility. It is often used for creating parts that require high strength and durability, such as gears and bearings. Nylon is more difficult to print with than other filaments and requires a higher printing temperature.

In addition to these common filaments, there are also specialty filaments available, such as wood, metal, and carbon fiber. These filaments are infused with particles of the respective material, giving the printed object the appearance and properties of that material.

In conclusion, 3D-printed plastic is commonly referred to as filament, and there are several types available for different applications. PLA is a biodegradable plastic that is easy to print with and environmentally friendly, while ABS is a strong and durable plastic used for functional parts. PETG combines the best properties of PLA and ABS, while nylon is known for its strength and flexibility. Specialty filaments are also available for creating objects with the appearance and properties of wood, metal, and carbon fiber.

Average Rating